Shoal Bay Waste Management Facility

Leachate Treatment System

To improve the operational management of the Shoal Bay Waste Management Facility (SBWMF) and to meet regulatory requirements, City of Darwin has identified the need for a Leachate Treatment system appropriate for the long-term operation of the site and post closure.

What is Leachate?

Leachate is water that has come into contact with waste and picked up contaminants along the way.

Through an extensive procurement process, City of Darwin awarded the development and construction of the facility to the Water and Carbon Group.

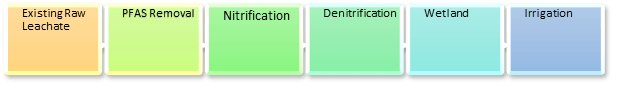

The leachate treatment process involves several different individual units that are incorporated together to form the full-scale plant. The individual units are used in different stages of the overall treatment process. The individual units are detailed below:

1) Existing 15 ML Leachate Collection Pond

This will manage seasonal changes in leachate production and reduce ‘spikes’ in leachate chemical concentrations.

2) PFAS Foaming

A foam fractionation process producing “Foamate” to reduce PFAS concentrations in the leachate.

3) Nitrification

Aerobic treatment of leachate to reduce ammonia concentrations to nitrate achieved through processes of the Sequencing Batch Reactor (SBR).

4) Denitrification

Anoxic treatment of leachate to reduce the nitrate to nitrogen gas achieved through processes of the proposed Moving Bed Biofilm Reactor (MBBR).

A dissolved air flotation device is used to remove the solids generated as part of the above processes form the leachate.

5) Wetland

Treated leachate will pass through a managed reed bed for sequestration of metals and facilitate additional ammonia volatilisation.

6) Irrigation

The treated leachate will be used to irrigate an area of vetiver grass on the final capping of Stages 3/4 of the landfill.

7) Monitoring

Baseline, quarterly and annual monitoring is proposed in-stream, and for soil and groundwater in the irrigation area and outside the irrigation area.

Originally the projects irrigation area was located outside the landfill’s footprint, however after a thorough investigation the irrigation area for treated leachate was relocated to the final cap of Stages 3/4. Relocating the irrigation area to within the landfill reduced the environmental risk of the project. Additionally, the proximity to the environmental receptors was improved with the more central location of the irrigation area increasing the distance to these potential receptors.

The proposed project presents a unique and innovative approach to solving the current and future issues created by leachate generation within the SBWMF landfill. By integrating the Leachate Treatment system into the final landfill cap of Stages 3 and 4, cost savings have been achieved in the initial capital expenditure and the ongoing operational and monitoring expenditure for the facility.